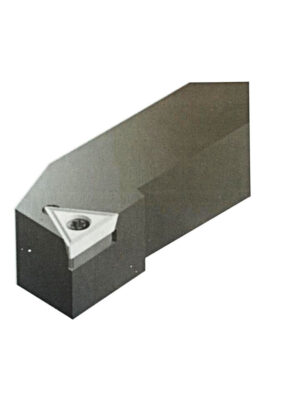

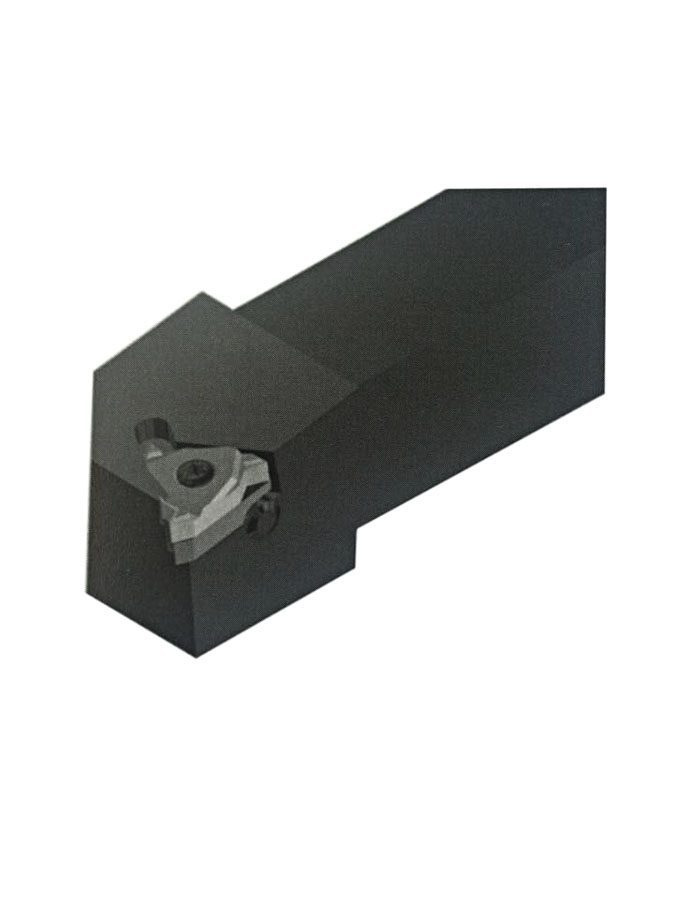

| DESCRIPTION | Threading Bar |

|---|---|

| MODEL | SXGNR 1212-F16 |

| APPROACH ANGLE | 90 Degrees |

| SHANK SIZE | 12.0 X 12.0mm |

| TOOL SIZE | F16 |

| INSERT TYPE | 16 ER |

| WEIGHT NETT/GROSS | 0.1/ 0.12kg |

| VOLUME | 0.0002cm |

| INSERT CODE |

Availability : Enquire Now

Price per Unit

ex-gst

$175.46Inc-gst

$201.78THREADING BAR: SXGNR 1212-F16 CANELA

Description

SKU : THB610220

Price per Unit

$175.46 (Exc GST)

$201.78 (Inc GST)

FEATURES:

Accessories: * Threading toolholder for negative lay down inserts * The screw clamping ensures a good and clean fixation * The insert is positioned a -10 degrees cutting angle and -1 degree clearance angle *

Applications: * Multipurpose threading toolholders *

| Weight | 0.12 kg |

|---|---|

| Dimensions | 0.15 × 0.04 × 0.04 cm |

Specifications

Description

Reviews (0)

Be the first to review “THREADING BAR: SXGNR 1212-F16 CANELA” Cancel reply

Shipping & Delivery

Related products

THREADING TOOL KIT: SER 1616H16 16.0MM

SKU:

LTA120240

$169.00

THREADING BAR SET: SXGNR 25 EXTERNAL

SKU:

THB610188

$289.80

Characteristics:

* Threading toolholder for negative laydown inserts

* The screw clamping ensures good stiffness and evacution of chips

* the insert is positioned a -10 Degrees cutting angle and a -1 Degree clearance angle

** Muitipurpose threading toolholders

*1 THREADING HOLDER 25mm SHANK

* 10 x THREADING INSERTS

* 16ER-AG55 16ER-AG60 16ER-075ISO 16ER-100ISO 16ER-125ISO 16ER-150ISO 16ER-175ISO 16ER-200ISO 16ER-250ISO 16ER-300ISO TD Tin 25 0grade

THREADING BAR: SXGNR 2525-M16 CANELA

SKU:

THB610228

$203.10

THREADING BAR: SXGNR 2525-M22 25.0 X 25.0MM CANELA

SKU:

THB610232

$203.10

THREADING BAR: SIR16 16 X 16 11IR 55/60DEG INSERT

SKU:

THB610242

$88.10

THREADING BAR: SIR20 20 X 20 11IR 55/60DEG INSERT

SKU:

THB610244

$94.00

THREADING BAR: SER-1212H-11 CHROME HOLDER

SKU:

THB624525

$110.00

THREADING INSERT: 27EL Q 55DEG L/HAND EXTERNAL

SKU:

THB700622

$292.51

* These carbide inserts are designed for left hand external threading

* Here are some tips for machining threads:

* To cut external threads, file the edges of the round rod first and then chamfer it at an angle of 45 degrees

* Ensure that when compared to the depth of the thread, the chamfer is bigger

* Include a chamfer to external thread end parts;

Ensure the starting end of a thread has a flat surface

* Also, ensure that it is consistent with the central axis of the thread

Reviews

There are no reviews yet.