| DESCRIPTION | Venturi |

|---|---|

| MODEL | Global 3000 |

| PART NUMBER | |

| TO SUIT | Global #000 |

| WEIGHT NETT/GROSS | |

| VOLUME |

Specifications

Description

Reviews (0)

Be the first to review “GLOBAL 3000: VENTURI” Cancel reply

Shipping & Delivery

Related products

GLOBAL 3000: HEATING TUBE FOR LASER

SKU:

LAS200907

$45.00

CNC LATHE/MILL: BOXFORD DUET

SKU:

LCN300120

$31,136.00

* The Boxford 'Duet' dual purpose CNC training Lathe/Mill is an ideal machine which has been specially designed for educational purposes * Comes with Boxford CAD/CAM software using world standard M&G codes * Drawings from other CAD applications can be imported and processed * Standard IBM compatible PC computer is required to handle the user-friendly software * Horizontal it can be used as a lathe - when stood on end it becomes a milling machine *

CNC LATHE: BOXFORD 160TCL

SKU:

LCN300130

$56,000.00

* The PC controlled Boxford 160TCL lathe is ideally suited to a class room environment and offers the perfect solution for hightech * The Boxford software is an integrated suite of powerful CAD/CAM tools * The machine rigidity and spindle torque allows a large variety of materials and components to be machined * Active and accurate tool path graphics continuously displayed line by line during program write test run and manufacture * Full perimeter guarding with interlocking switches on access doors arranged in the positive (saftey) mode for spindle stop and feed hold * Latching emergency stop button * Low voltage control circuitry *

CNC LATHE: BOXFORD T220

SKU:

LCN300150

$0.00

BOXFORD: A3RTCM2EX CNC Router

SKU:

MMC400050

$78,635.00

CNC ROUTER 3015 3000 X 1500MM

SKU:

MMC400055

$75,000.00

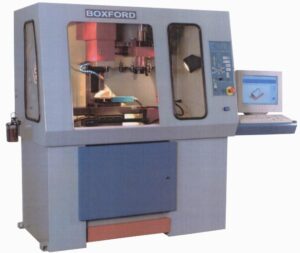

BOXFORD: 300VMC TABLE 505 X 135MM.

SKU:

MMC400130

$0.00

* The Boxford software is an integrated suite of powerful CAD/CAM tools

* The CAD provides a variety of drawing tools including text fonts with excellent manipulation routines

* Drawing from other CAD applications can also be imported and processed

* Manual Data Input allows programs to be entered using International Industrial programming conventions

* Touch sensitive control panel incorporating illuminated push buttons allows the machine to be operated without a computer

* Active and accurate tool path graphics continuously displayed line by line during program write test run and manufacture

Reviews

There are no reviews yet.