- Show All

- AUTO RECONDITIONING MACHINES

- AXLE STANDS

- BATTERY CHARGERS

- ENGINE STANDS

- GREASE & OILS

- HYDRAULIC BODY JACKS

- HYDRAULIC BOTTLE JACKS

- HYDRAULIC TOE JACKS

- HYDRAULIC TROLLEY JACKS

- HYD ENGINE CRANES

- HYD MOTORCYCLE LIFT

- HYD TRANSMISSION JACKS

- HYD SPRING COMPRESSOR

- HYD VEHICLE POSITIONING JACK

- GARAGE ESSENTIALS

- OIL DRAIN TANK

- PANEL BEATING EQUIPMENT

- WORKSHOP PRESSES

COLLET: ER32 15.0MM

SKU:

CER700214

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER32 16.0MM

SKU:

CER700216

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER32 17.0MM

SKU:

CER700218

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER32 18.0MM

SKU:

CER700220

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER32 19.0MM

SKU:

CER700222

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER32 20.0MM

SKU:

CER700224

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

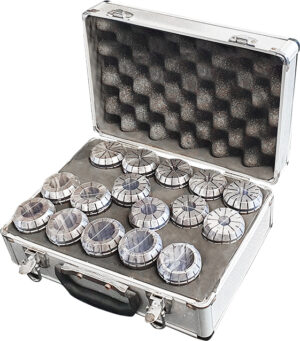

COLLET SET: ER40 24PC 3.0MM TO 26.0MM

SKU:

CER700226

* This is an 24pc ER40 collets set with range from 3.0mm to 26.0mm

* This is an 8pc ER16 collets set with range from 3.0mm to 10.0mm

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines

* The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 03.0MM

SKU:

CER700228

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 04.0MM

SKU:

CER700230

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 05.0MM

SKU:

CER700232

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 06.0MM

SKU:

CER700234

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 07.0MM

SKU:

CER700236

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 08.0MM

SKU:

CER700238

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 09.0MM

SKU:

CER700240

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 10.0MM

SKU:

CER700242

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 11.0MM

SKU:

CER700244

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 12.0MM

SKU:

CER700246

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 13.0MM

SKU:

CER700248

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 14.0MM

SKU:

CER700250

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 15.0MM

SKU:

CER700252

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 16.0MM

SKU:

CER700254

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 17.0MM

SKU:

CER700256

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 18.0MM

SKU:

CER700258

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 19.0MM

SKU:

CER700260

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 20.0MM

SKU:

CER700262

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 21.0MM

SKU:

CER700264

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 22.0MM

SKU:

CER700266

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 23.0MM

SKU:

CER700268

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 24.0MM

SKU:

CER700270

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 25.0MM

SKU:

CER700272

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER40 26.0MM

SKU:

CER700274

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET SET: ER50 16PC SET 6.0MM TO 36.0MM

SKU:

CER700280

* This is an 16pc ER50 collets set with range from 6.0mm to 32.0mm

* This is an 8pc ER16 collets set with range from 3.0mm to 10.0mm

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines

* The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER50 06.0MM

SKU:

CER700284

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER50 08.0MM

SKU:

CER700288

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER50 10.0MM

SKU:

CER700292

* These ER collets are manufactured to DIN 6499 standard

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day.

COLLET: ER50 12.0MM

SKU:

CER700296

* These ER collets are manufactured to DIN 6499 standard

* Manufactured from quality 65Mn spring steel - hardness HRC44-48

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day

COLLET: ER50 14.0MM

SKU:

CER700300

* These ER collets are manufactured to DIN 6499 standard

* Manufactured from quality 65Mn spring steel - hardness HRC44-48

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day

COLLET: ER50 16.0MM

SKU:

CER700304

* These ER collets are manufactured to DIN 6499 standard

* Manufactured from quality 65Mn spring steel - hardness HRC44-48

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day

COLLET: ER50 18.0MM

SKU:

CER700308

* These ER collets are manufactured to DIN 6499 standard

* Manufactured from quality 65Mn spring steel - hardness HRC44-48

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day

COLLET: ER50 20.0MM

SKU:

CER700312

* These ER collets are manufactured to DIN 6499 standard

* Manufactured from quality 65Mn spring steel - hardness HRC44-48

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day

COLLET: ER50 22.0MM

SKU:

CER700316

* These ER collets are manufactured to DIN 6499 standard

* Manufactured from quality 65Mn spring steel - hardness HRC44-48

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day

COLLET: ER50 24.0MM

SKU:

CER700320

* These ER collets are manufactured to DIN 6499 standard

* Manufactured from quality 65Mn spring steel - hardness HRC44-48

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day

COLLET: ER50 26.0MM

SKU:

CER700324

* These ER collets are manufactured to DIN 6499 standard

* Manufactured from quality 65Mn spring steel - hardness HRC44-48

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day

COLLET: ER50 28.0MM

SKU:

CER700328

* These ER collets are manufactured to DIN 6499 standard

* Manufactured from quality 65Mn spring steel - hardness HRC44-48

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day

COLLET: ER50 30.0MM

SKU:

CER700332

* These ER collets are manufactured to DIN 6499 standard

* Manufactured from quality 65Mn spring steel - hardness HRC44-48

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day

COLLET: ER50 32.0MM

SKU:

CER700336

* These ER collets are manufactured to DIN 6499 standard

* Manufactured from quality 65Mn spring steel - hardness HRC44-48

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day

COLLET: ER50 34.0MM

SKU:

CER700340

* These ER collets are manufactured to DIN 6499 standard

* Manufactured from quality 65Mn spring steel - hardness HRC44-48

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day

COLLET: ER50 36.0MM

SKU:

CER700344

* These ER collets are manufactured to DIN 6499 standard

* Manufactured from quality 65Mn spring steel - hardness HRC44-48

* Used in a wide variety of milling chucks for CNC and conventional machines

* ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool.

An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA

* Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets

* This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day

COLLET: ER32C 2.0-1.0MM SEAL TYPE

SKU:

CER700500

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

RD

20

40

60

70

80

90

COLLET: ER32C 3.0-2.0MM SEAL TYPE

SKU:

CER700501

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 4.0-3.0MM SEAL TYPE

SKU:

CER700502

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 5.0-4.0MM SEAL TYPE

SKU:

CER700503

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 6.0-5.0MM SEAL TYPE

SKU:

CER700504

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 7.0-6.0MM SEAL TYPE

SKU:

CER700505

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 8.0-7.0MM SEAL TYPE

SKU:

CER700506

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 9.0-8.0MM SEAL TYPE

SKU:

CER700507

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 10.0-9.0MM SEAL TYPE

SKU:

CER700508

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 11.0-10.0MM SEAL TYPE

SKU:

CER700509

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 12.0-11.0MM SEAL TYPE

SKU:

CER700510

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 13.0-12.0MM SEAL TYPE

SKU:

CER700511

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 14.0-13.0MM SEAL TYPE

SKU:

CER700512

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 15.0-14.0MM SEAL TYPE

SKU:

CER700513

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 16.0-15.0MM SEAL TYPE

SKU:

CER700514

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 17.0-16.0MM SEAL TYPE

SKU:

CER700515

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 18.0-17.0MM SEAL TYPE

SKU:

CER700516

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 19.0-18.0MM SEAL TYPE

SKU:

CER700517

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER32C 20.0-19.0MM SEAL TYPE

SKU:

CER700518

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER40C 6.0-5.0MM SEAL TYPE

SKU:

CER700522

** All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER40C 8.0-7.0MM SEAL TYPE

SKU:

CER700524

** All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER40C 10.0-9.0MM SEAL TYPE

SKU:

CER700528

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER40C 12.0-11.0MM SEAL TYPE

SKU:

CER700530

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER40C 14.0-13.0MM SEAL TYPE

SKU:

CER700534

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER40C 16.0-15.0MM SEAL TYPE

SKU:

CER700538

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER40C 18.0-17.0MM SEAL TYPE

SKU:

CER700542

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER40C 20.0-19.0MM SEAL TYPE

SKU:

CER700546

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER40C 21.0-20.0MM SEAL TYPE

SKU:

CER700548

* All ER collets are hardened and pricision ground for accuracy

* These collest are for through hole coolant and normally used on CNC machines

* Sealed ER Collets for coolant through applications do not have a collapse range, and must be used at exact size

* The radius of the collet must exactly match the radius of the cutting tool shank in order to maintain a complete seal

* If companies claim that they have sealed collets with a collapse range please keep in mind that if the radius does not match exactly coolant canals will be created by the mismatched radius of an improperly sized collet.

* ER Collets must be tightened correctly

* Many machinists have been trained that nothing is ever too tight

* This is particularly not true with collets and collet chucks. * Overtightening a collet chuck will distort the collet and actually diminish the holding strength and accuracy. * Maximum tightening torque for ER Systems is as follows:

RER 11 20 Max. Tightening Torque (ft. lbs.) ER 25 70

EER 16 40 ER 32 80

RER 20 60 ER 40 90

COLLET: ER40C 22.0-21.0MM SEAL TYPE