- Show All

- AUTO RECONDITIONING MACHINES

- AXLE STANDS

- BATTERY CHARGERS

- ENGINE STANDS

- GREASE & OILS

- HYDRAULIC BODY JACKS

- HYDRAULIC BOTTLE JACKS

- HYDRAULIC TOE JACKS

- HYDRAULIC TROLLEY JACKS

- HYD ENGINE CRANES

- HYD MOTORCYCLE LIFT

- HYD TRANSMISSION JACKS

- HYD SPRING COMPRESSOR

- HYD VEHICLE POSITIONING JACK

- GARAGE ESSENTIALS

- OIL DRAIN TANK

- PANEL BEATING EQUIPMENT

- WORKSHOP PRESSES

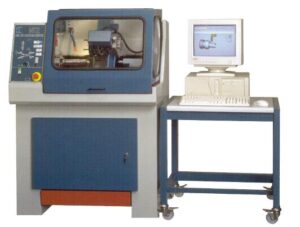

CNC MILLING CENTRE: GL550L

$30,000.00

* CNC milling machine fitted with Seimens 808D controller

* Spindle taper is ISO20

* Fitted with 12 station ATC

* Comes with linear guide, matched with all servo motors

* This will ensure higher speed and accuracy

* Ideal training machine or small production centre

* Sfandard is fitted with jacking feet for leveling

* Two door cabinet storage for all accessories

| Weight | 1050 kg |

|---|---|

| Dimensions | 2 × 1.3 × 2 cm |

In stock

SKU:

MMC400250

Category: EDUCATIONAL CNC MACHINE

Description

| CONTROLLER | Siemens 808D |

|---|---|

| WORKING SURFACE | 550 x 160mm |

| TRAVEL XYZ | 270mm x 152 x 270mm |

| SPINDLE TO TABLE | 80-350mm |

| MAX TABLE LOAD | 30 Kg |

| SPINDLE SPEED | 100-5000rpm |

| SPINDLE TAPER | ISO 20 |

| CUTTING FEED RATE | |

| RAPID TRAVERSE XY | 2000mm/min |

| RAPID TRAVERSE Z | 1500mm/m |

| ATC TYPE | Umbrella |

| TOOL STORAGE CAP | 12 |

| SPINDLE MOTOR | 1000watt |

| POWER CONSUMPTION | |

| WEIGHT NETT/GROSS | 390/ 450kg |

| VOLUME | 5.200cm |

| FLOOR SPACE L X W X H | 1280 x 895 x 1845mm |

| PACKING SIZE L x W x H | 2000 x 1300 x 2060mm |

Shipping & Delivery

Related products

GLOBAL 3000: HEATING TUBE FOR LASER

SKU:

LAS200907

$45.00

CNC LATHE: BOXFORD 160TCL

SKU:

LCN300130

$56,000.00

* The PC controlled Boxford 160TCL lathe is ideally suited to a class room environment and offers the perfect solution for hightech * The Boxford software is an integrated suite of powerful CAD/CAM tools * The machine rigidity and spindle torque allows a large variety of materials and components to be machined * Active and accurate tool path graphics continuously displayed line by line during program write test run and manufacture * Full perimeter guarding with interlocking switches on access doors arranged in the positive (saftey) mode for spindle stop and feed hold * Latching emergency stop button * Low voltage control circuitry *

CNC LATHE/MILL: BOXFORD MT2

SKU:

LCN300140

$0.00

* The PC controlled Boxford MT2 combined lathe and mill is ideally suited to a classroom environment and offers the perfect solution for high tech * The unique combination Lathe Turret and 3rd Mill Axix allows steel to be cut to close tolerances * The Boxford software is an integrated suite of powerful CAD/CAM tools * As with all Boxford PC machines the MT2 incorporates hardware capable of continuous 3 axis movement and utilises Continuous Path Manufacture allowing large programs imported from Major CAD/CAM packages to be machined extremely efficiently:- This is particularly useful for Rapid Prototyping of 3D reliefs * Touch sensitive control panel incorporating illuminated push buttons allows the machines to be operated without a computer * Overload cut-out on spindle drive *

CNC LATHE: BOXFORD 250PC

SKU:

LCN300160

$0.00

* Automatic CAM software * Operates from variety of computers * Cuts steel brass aluminium & plastic * 3D graphics * Slant bed construction * Operated by personal computer the 250PC Training Computer Lathe is ideally suited for all training requirements * CAM User friendly Software with 3D grphical simulation & automatic error checking * Constant surface speed * Single phase electricity power supply gives easy installation * 2 Feed modes (per rev / per min) * Links with 300VMC machining centre and robots in an FMS system *

GL550 ACCESSORY-COOLANT SYSTEM

SKU:

MMC400262

$295.00