- Show All

- AUTO RECONDITIONING MACHINES

- AXLE STANDS

- BATTERY CHARGERS

- ENGINE STANDS

- GREASE & OILS

- HYDRAULIC BODY JACKS

- HYDRAULIC BOTTLE JACKS

- HYDRAULIC TOE JACKS

- HYDRAULIC TROLLEY JACKS

- HYD ENGINE CRANES

- HYD MOTORCYCLE LIFT

- HYD TRANSMISSION JACKS

- HYD SPRING COMPRESSOR

- HYD VEHICLE POSITIONING JACK

- GARAGE ESSENTIALS

- OIL DRAIN TANK

- PANEL BEATING EQUIPMENT

- WORKSHOP PRESSES

BOXFORD: 300VMC TABLE 505 X 135MM.

$0.00

* The Boxford software is an integrated suite of powerful CAD/CAM tools

* The CAD provides a variety of drawing tools including text fonts with excellent manipulation routines

* Drawing from other CAD applications can also be imported and processed

* Manual Data Input allows programs to be entered using International Industrial programming conventions

* Touch sensitive control panel incorporating illuminated push buttons allows the machine to be operated without a computer

* Active and accurate tool path graphics continuously displayed line by line during program write test run and manufacture

| Weight | 500 kg |

|---|---|

| Dimensions | 1.425 × 0.81 × 0.6 cm |

SKU:

MMC400130

Category: EDUCATIONAL CNC MACHINE

Description

| CONTROLLER | Boxford |

|---|---|

| WORKING SURFACE | 505mm X 135mm |

| TRAVEL XYZ | 304mm X 157mm X 213mm |

| SPINDLE TO TABLE | 260mm |

| MAX TABLE LOAD | |

| SPINDLE SPEED | 200 – 4000rpm |

| SPINDLE TAPER | |

| CUTTING FEED RATE | 0 – 5000 mm/min |

| RAPID TRAVERSE XY | 5000 mm/min |

| RAPID TRAVERSE Z | 5000 mm/min |

| ATC TYPE | Option |

| TOOL STORAGE CAP | Option 6 – 8 Station |

| SPINDLE MOTOR | 1.26 Kw |

| POWER CONSUMPTION | |

| WEIGHT NETT/GROSS | 500 Kg/ |

| VOLUME | 0.6926cm |

| FLOOR SPACE | 1425mm X 810mm |

Shipping & Delivery

Related products

LASER / CNC MILL / 3D PRINTING BENZEL

SKU:

LAS200900

$13,000.00

CNC LATHE/MILL: BOXFORD DUET

SKU:

LCN300120

$31,136.00

* The Boxford 'Duet' dual purpose CNC training Lathe/Mill is an ideal machine which has been specially designed for educational purposes * Comes with Boxford CAD/CAM software using world standard M&G codes * Drawings from other CAD applications can be imported and processed * Standard IBM compatible PC computer is required to handle the user-friendly software * Horizontal it can be used as a lathe - when stood on end it becomes a milling machine *

CNC LATHE: BOXFORD 160TCL

SKU:

LCN300130

$56,000.00

* The PC controlled Boxford 160TCL lathe is ideally suited to a class room environment and offers the perfect solution for hightech * The Boxford software is an integrated suite of powerful CAD/CAM tools * The machine rigidity and spindle torque allows a large variety of materials and components to be machined * Active and accurate tool path graphics continuously displayed line by line during program write test run and manufacture * Full perimeter guarding with interlocking switches on access doors arranged in the positive (saftey) mode for spindle stop and feed hold * Latching emergency stop button * Low voltage control circuitry *

CNC LATHE: BOXFORD T220

SKU:

LCN300150

$0.00

CNC LATHE: BOXFORD 250PC

SKU:

LCN300160

$0.00

* Automatic CAM software * Operates from variety of computers * Cuts steel brass aluminium & plastic * 3D graphics * Slant bed construction * Operated by personal computer the 250PC Training Computer Lathe is ideally suited for all training requirements * CAM User friendly Software with 3D grphical simulation & automatic error checking * Constant surface speed * Single phase electricity power supply gives easy installation * 2 Feed modes (per rev / per min) * Links with 300VMC machining centre and robots in an FMS system *

CNC ROUTER: MG1630D ATC

SKU:

MMC400056

$68,000.00

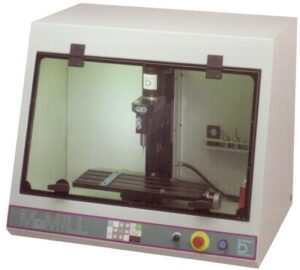

BOXFORD: MIDI TABLE 145 X 153MM

SKU:

MMC400110

$0.00

* Dovetail slide construction

* Anti-Backlash nuts on all axes

* Three axis simultaneous operation

* Fully enclosed see through guarding for saftey and improved viewing

* Integrated electrical panel

* The PC controlled Boxford MidiMILL Vertical Machining Centre

* Operating on PC computer the inclusive user-friendly software has routines for Computer Aided Design (CAD) at both simple and sophisticated levels and will process designed components through to a full machining routine

* Latching emergency stop button

* Low voltage control circuitry