- Show All

- AUTO RECONDITIONING MACHINES

- AXLE STANDS

- BATTERY CHARGERS

- ENGINE STANDS

- GREASE & OILS

- HYDRAULIC BODY JACKS

- HYDRAULIC BOTTLE JACKS

- HYDRAULIC TOE JACKS

- HYDRAULIC TROLLEY JACKS

- HYD ENGINE CRANES

- HYD MOTORCYCLE LIFT

- HYD TRANSMISSION JACKS

- HYD SPRING COMPRESSOR

- HYD VEHICLE POSITIONING JACK

- GARAGE ESSENTIALS

- OIL DRAIN TANK

- PANEL BEATING EQUIPMENT

- WORKSHOP PRESSES

BLADE: HSS 300 X 2.5 X 32 BLANK 1HUNO30025008 BRAVO BLU

SKU:

COB200362S

* DM05 BRAVO BLU that are a TIALN coated blades - this means you can cut faster

* Even without water

* Made with traditional DM05 material

* Used in all the world as a cutting upgrade

* Stark metal cutting saw blades are manufactured for durability and long service life

* These Stark saw blades are made in their own factory in Italy

BLADE: HSS 300 X 2 X 40 BLANK KINKELDA

SKU:

COB200370

* Kinkelder metal cutting saw blades are manufactured in Holland

* Made from quality HSS for durability and long service life

* These quality saw blades are famous in Europe for their quality

* Blank blades are for individuals that require a special purpose blade and can grind their own teeth to suit

BLADE: HSS 315 x 2.5 x 32 BLANK KINKELDA

SKU:

COB200376

* Kinkelder metal cutting saw blades are manufactured in Holland

* Made from quality HSS for durability and long service life

* These quality saw blades are famous in Europe for their quality

* Blank blades are for individuals that require a special purpose blade and can grind their own teeth to suit

BLADE: HSS 315 X 2.5X40 BLANK KINKELDA

SKU:

COB200380

* Kinkelder metal cutting saw blades are manufactured in Holland

* Made from quality HSS for durability and long service life

* These quality saw blades are famous in Europe for their quality

* Blank blades are for individuals that require a special purpose blade and can grind their own teeth to suit

BLADE: HSS 350 X 2.5 X 32 BLANK KINKELDA

SKU:

COB200390

* Kinkelder metal cutting saw blades are manufactured in Holland

* Made from quality HSS for durability and long service life

* These quality saw blades are famous in Europe for their quality

* Blank blades are for individuals that require a special purpose blade and can grind their own teeth to suit

BLADE: HSS 350 X 2.5 X 40 BLANK KINKELDA

SKU:

COB200400

* Kinkelder metal cutting saw blades are manufactured in Holland

* Made from quality HSS for durability and long service life

* These quality saw blades are famous in Europe for their quality

* Blank blades are for individuals that require a special purpose blade and can grind their own teeth to suit

BLADE: HSS 400 X 3 X 40 BLANK KINKELDA

SKU:

COB200410

* Kinkelder metal cutting saw blades are manufactured in Holland

* Made from quality HSS for durability and long service life

* These quality saw blades are famous in Europe for their quality

* Blank blades are for individuals that require a special purpose blade and can grind their own teeth to suit

BLADE: HSS 500 X 4 X 40 X 420T Brobo

SKU:

COB200480

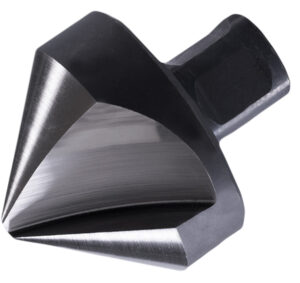

COUNTER SINK BIT: HSS 10-31.0MM 3 FLUTE MT2 TAPER

SKU:

CTB2803370

* This large three flute countersink is manufactured fron HSS-C05

* This offers durability and long service life for this cutter

* Comes with MT2 shank to suit drilling machines

Choosing the Right Countersink

How to Choose the Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 10-40.0MM 3 FLUTE MT3 TAPER

SKU:

CTB2803380

* This large three flute countersink is manufactured fron HSS-M2

* This offers durability and long service life for this cutter

* Comes with MT2 shank to suit drilling machines

Choosing the Right Countersink

How to Choose the Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 10-50.0MM 3 FLUTE MT3 TAPER

SKU:

CTB2803382

* This large three flute countersink is manufactured fron HSS-C05

* This offers durability and long service life for this cutter

* Comes with MT3 shank to suit drilling machines

Choosing the Right Countersink

How to Choose the Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 10-63.0MM 3 FLUTE MT4 TAPER

SKU:

CTB2803390

* This large three flute countersink is manufactured fron HSS-C05

* This offers durability and long service life for this cutter

* Comes with MT4 shank to suit drilling machines

Choosing the Right Countersink

How to Choose the Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 10-80.0MM 3 FLUTE MT4 TAPER

SKU:

CTB2803392

* This large three flute countersink is manufactured fron HSS-M2

* This offers durability and long service life for this cutter

* Comes with MT2 shank to suit drilling machines

Choosing the Right Countersink

How to Choose the Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 10-40.0MM 3 FLUTE (WELDON SHANK)

SKU:

CTB2803400

* This large three flute countersink is manufactured fron HSS-M2

* This offers durability and long service life for this cutter

* Comes with Weldon shanks to suit magnetic drilling machines

* Weldon shanks are 19.0mm in diameter

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 10-50.0MM 3 FLUTE (WELDON SHANK)

SKU:

CTB2803402

* This large three flute countersink is manufactured fron HSS-M2

* This offers durability and long service life for this cutter

* Comes with Weldon shanks to suit magnetic drilling machines

* Weldon shanks are 19.0mm in diameter

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 15-63.0MM 3 FLUTE (WELDON SHANK)

SKU:

CTB2803404

* This large three flute countersink is manufactured fron HSS-M2

* This offers durability and long service life for this cutter

* Comes with Weldon shanks to suit magnetic drilling machines

* Weldon shanks are 19.0mm in diameter

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 1/4″ SINGLE FLUTE 1/4″ SHANK 90D

SKU:

CTB2841402

* This single flute countersink bit is manufactured from quality HSS-M2

* This offers durability and long service life

* Comes with 1/4" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 3/8″ SINGLE FLUTE 1/4″ SHANK 90D

SKU:

CTB2841404

* This single flute countersink bit is manufactured from quality HSS-M2

* This offers durability and long service life

* Comes with 1/4" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 1/2″ SINGLE FLUTE 1/4″ SHANK 90D

SKU:

CTB2841406

* This single flute countersink bit is manufactured from quality HSS-M2

* This offers durability and long service life

* Comes with 1/4" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 3/4″ SINGLE FLUTE 1/2″ SHANK 90D

SKU:

CTB2841408

* This single flute countersink bit is manufactured from quality HSS-M2

* This offers durability and long service life

* Comes with 1/2" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 1″ SINGLE FLUTE 1/2″ SHANK 90D

SKU:

CTB2841410

* This single flute countersink bit is manufactured from quality HSS-M2

* This offers durability and long service life

* Comes with 1/2" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 1/4″ THREE FLUTE 1/4″ SHANK 90D

SKU:

CTB2843402

* This three flute countersink bit is manufactured from quality HSS-M2

* This offers durability and long service life

* Comes with 1/4" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 3/8″ THREE FLUTE 1/4″ SHANK 90D

SKU:

CTB2843404

* This Three flute countersink bit is manufactured from quality HSS-M2

* This offers durability and long service life

* Comes with 1/4" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 1/2″ THREE FLUTE 1/4″ SHANK 90D

SKU:

CTB2843406

* This Three flute countersink bit is manufactured from quality HSS-M2

* This offers durability and long service life

* Comes with 1/4" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 3/4″ THREE FLUTE 1/2″ SHANK 90D

SKU:

CTB2843408

* This Three flute countersink bit is manufactured from quality HSS-M2

* This offers durability and long service life

* Comes with 1/2" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 1″ THREE FLUTE 1/2″ SHANK 82D

SKU:

CTB2843410

* This Three flute countersink bit is manufactured from quality HSS-M2

* This offers durability and long service life

* Comes with 1/2" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 4-31.0MM 3 FLUTE 1/2″ SHANK

SKU:

CTB2843412

* This Three flute countersink bit is manufactured from quality HSS-M2

* This offers durability and long service life

* Comes with 1/2" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 8-40.0MM 3 FLUTE 1/2″ SHANK

SKU:

CTB2843414

* This Three flute countersink bit is manufactured from quality HSS-M2

* This offers durability and long service life

* Comes with 1/2" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 10-50.0mm 3 FLUTE 1/2″ SHANK

SKU:

CTB2843416

* This Three flute countersink bit is manufactured from quality HSS-C05 (5% Cobolt)

* This offers durability and long service life

* Comes with 1/2" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 12-60.0MM 3 FLUTE 1/2″ SHANK

SKU:

CTB2843418

* This large Three flute countersink bit is manufactured from quality HSS-M2

* This offers durability and long service life

* Comes with 1/2" shank

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT INSERT: SUIT 7-44MM CHAM-SINK NEW

SKU:

CTB2843608

COUNTER SINK BIT INSERT: SUIT 7-44MM OLD TYPE

SKU:

CTB2843611

COUNTER SINK BIT INSERT: SUIT 12-54MM COUNTERSINK

SKU:

CTB2843614

COUNTER SINK BIT INSERT: SUIT 284-3618 (PER EACH)

SKU:

CTB2843615

COUNTER SINK BIT: 7- 44.0MM (3 INSERTS) (WELDON SHANK)

SKU:

CTB2843616

COUNTER SINK BIT: 7- 44.0MM (3 INSERTS) 16MM (S/SHANK)

SKU:

CTB2843618

* This large heavy duty countersink bit comes with 13,0mm shank

* This countersink bit takes 3pc carbide inserts set at 90deg

Well balanced with less chatter

* Insert code is CTB8243618

* Cuts upto 60HRC

* Designed to countersink difficult and hard materials like flame cut stainless stel or wear plate

COUNTER SINK BIT: 18-38.0MM (1 X INSERT) 12.0MM SHANK

SKU:

CTB2843620

COUNTER SINK BIT: 12-54.0MM (3 INSERT) 16.0MM SHANK 90D

SKU:

CTB2843624

COUNTER SINK BIT: 12-54.0MM (3 INSERT) WELDON SHANK 90D

SKU:

CTB2843626

COUNTER SINK BIT: 12-54.0MM (3 INSERT) 25.0MM SHANK 90D

SKU:

CTB2843628

COUNTER SINK BIT: 1/2″ to 1-3/4″ 1 X TPGH433 1 X INSERT

SKU:

CTB2843630

COUNTER SINK BIT: 1-1/4″ to 2-1/2″ 3/4″ SHANK 1 X INSERT

SKU:

CTB2843634

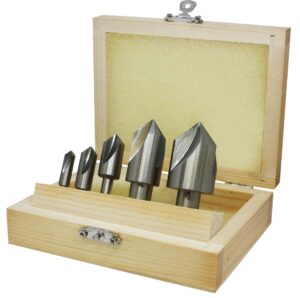

COUNTER SINK SET: HSS 3 FLUTE 5PC SET 1/4″-1″ 90DEG

SKU:

CTB2845000

* This 5pc countersink bit set is manufactured from quality HSS-M2

* Range is from 1/4, 3/8, 1/2, 3/4, 1"

* Angle is 90 degree

* Shank size is 1/4" and 1/2"

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK SET: HSS 3 FLUTE 6PC SET 6.3-20.5MM 90DEG

SKU:

CTB2845010

* This 6pc countersink bit set is manufactured from quality HSS-M2

* Range: 6.3, 8.3, 10.4, 12.4, 16.5, 20.5mm

* Angle is 90 degree

* Choosing the right Countersink

* How to Choose the right Size countersink by diameter !

* A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

* Countersink diameter = 1.5 x bolt size (hole) diameter

* Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375

* This equates to a 3/8” countersink

* How to Choose the right size countersink by angle !

* Angle is based on the screw or bolt type being used

* 82º is most common

* Supplied in quality plactic case for safe storage

COUNTER SINK SET: HSS 3 FLUTE 6PC SET 4.3-12.4MM 90DEG

SKU:

CTB2845020

* Small three flute set of counter sink bits

* Comes with wooden box for safe storage

* Manufactured from quality HSS-M2 for durability and long service life

* Sizes include: 4.3, 5.3, 6.3, 8.0, 10.0, 12.4mm

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 4PC HOLE TYPE SET 2.0-20MM 90DEG

SKU:

CTB2845040

* This hole type countersink bit 4pc set

* Manufactured from quality HSS-M2 for durability and long service life

* Bit ranges are: 2-5mm 5-10mm 10-15mm 15-20mm

* Suitable for countersinking or deburring

* Angle is 90 degree

Choosing the Right Countersink

How to Choose The Right Size Countersink by Diameter

A simple rule of thumb is to choose a countersink which is 50% larger than the diameter of the hole

Countersink diameter = 1.5 x bolt size (hole) diameter

Ex: For a 1/4-20 bolt, multiply the diameter (.250) x 1.5 = .375. This equates to a 3/8” countersink

How to Choose The Right Size Countersink by Angle

Angle is based on the screw or bolt type being used

82º is most common

COUNTER SINK BIT: HSS 5PC HOLE TYPE SET 2.5-25MM 90DEG

SKU:

CTB2845045

COUNTER SINK BIT: 10.0 – 15.0MM CROSS HOLE TYPE 90D

SKU:

CTB300104

COUNTER SINK BIT: 15.0 – 20.0MM CROSS HOLE TYPE 90D

SKU:

CTB300106

COUNTER SINK BIT: 25.0 – 30.0MM CROSS HOLE TYPE 90D

SKU:

CTB300114

COUNTER SINK BIT: 30.0 – 35.0MM CROSS HOLE TYPE

SKU:

CTB300118

COUNTER SINK BIT: 35.0 – 40.0MM CROSS HOLE TYPE 90D

SKU:

CTB300119

COUNTER SINK BIT: 40.0 – 50.0MM CROSS HOLE TYPE 90D

SKU:

CTB300230

COUNTER SINK BIT: 25-45mm (1 INSERT) 12mm SHANK-c/wWear strip

SKU:

CTB300242

* This is a very special countersink bit with long tool life

* The body has three cabide inserts to protect ware on the body of this tool

* Has one replaceable insert which has three cutting edges

Comes mounted on 12.0mm shank

Carbide wear blanks are replaceable should they ever ware out

* A very special countersink which has won aclaim from many end users !

* Available in two sizes 5-25mm & 25-45mm

COUNTER SINK: 6.0MM HSSCo 3 FLUTE 90° ANTI-CHATTER

SKU:

CTB300308

* These three flute countersink Bit are manufactured by Hartingen

* Special spiral flute 90 degree geometry with unequil helix angles

* High grade HSSCo substrates hold up well in high-tempreture applications

* Low vibration without chatter marks

* The tianin coating ensures higher wear resistance

* Reduction in axial force by 50%

* Reduction in radial force by 25%

* German technology at a fraction of the cost

COUNTER SINK: 8.0MM HSSCo 3 FLUTE 90° ANTI-CHATTER

SKU:

CTB300316

* These three flute countersink Bit are manufactured by Hartingen

* Special spiral flute 90 degree geometry with unequil helix angles

* High grade HSSCo substrates hold up well in high-tempreture applications

* Low vibration without chatter marks

* The tianin coating ensures higher wear resistance

* Reduction in axial force by 50%

* Reduction in radial force by 25%

* German technology at a fraction of the cost

COUNTER SINK: 10.0MM HSSCo 3 FLUTE 90° ANTI-CHATTER

SKU:

CTB300320

* These three flute countersink Bit are manufactured by Hartingen

* Special spiral flute 90 degree geometry with unequil helix angles

* High grade HSSCo substrates hold up well in high-tempreture applications

* Low vibration without chatter marks

* The tianin coating ensures higher wear resistance

* Reduction in axial force by 50%

* Reduction in radial force by 25%

* German technology at a fraction of the cost

COUNTER SINK: 12.4MM HSSCo 3 FLUTE 90° ANTI-CHATTER

SKU:

CTB300328

* These three flute countersink Bit are manufactured by Hartingen

* Special spiral flute 90 degree geometry with unequil helix angles

* High grade HSSCo substrates hold up well in high-tempreture applications

* Low vibration without chatter marks

* The tianin coating ensures higher wear resistance

* Reduction in axial force by 50%

* Reduction in radial force by 25%

* German technology at a fraction of the cost

COUNTER SINK: 14.4MM HSSCo 3 FLUTE 90° ANTI-CHATTER

SKU:

CTB300332

* These three flute countersink Bit are manufactured by Hartingen

* Special spiral flute 90 degree geometry with unequil helix angles

* High grade HSSCo substrates hold up well in high-tempreture applications

* Low vibration without chatter marks

* The tianin coating ensures higher wear resistance

* Reduction in axial force by 50%

* Reduction in radial force by 25%

* German technology at a fraction of the cost

COUNTER SINK: 16.5MM HSSCo 3 FLUTE 90° ANTI-CHATTER

SKU:

CTB300336

* These three flute countersink Bit are manufactured by Hartingen

* Special spiral flute 90 degree geometry with unequil helix angles

* High grade HSSCo substrates hold up well in high-tempreture applications

* Low vibration without chatter marks

* The tianin coating ensures higher wear resistance

* Reduction in axial force by 50%

* Reduction in radial force by 25%

* German technology at a fraction of the cost

COUNTER SINK: 20.5MM HSSCo 3 FLUTE 90° ANTI-CHATTER

SKU:

CTB300340

* These three flute countersink Bit are manufactured by Hartingen

* Special spiral flute 90 degree geometry with unequil helix angles

* High grade HSSCo substrates hold up well in high-tempreture applications

* Low vibration without chatter marks

* The tianin coating ensures higher wear resistance

* Reduction in axial force by 50%

* Reduction in radial force by 25%

* German technology at a fraction of the cost

COUNTER SINK: 23.0MM HSSCo 3 FLUTE 90° ANTI-CHATTER

SKU:

CTB300344

* These three flute countersink Bit are manufactured by Hartingen

* Special spiral flute 90 degree geometry with unequil helix angles

* High grade HSSCo substrates hold up well in high-tempreture applications

* Low vibration without chatter marks

* The tianin coating ensures higher wear resistance

* Reduction in axial force by 50%

* Reduction in radial force by 25%

* German technology at a fraction of the cost

COUNTER SINK: 25.0MM HSSCo 3 FLUTE 90° ANTI-CHATTER

SKU:

CTB300348

* These three flute countersink Bit are manufactured by Hartingen

* Special spiral flute 90 degree geometry with unequil helix angles

* High grade HSSCo substrates hold up well in high-tempreture applications

* Low vibration without chatter marks

* The tianin coating ensures higher wear resistance

* Reduction in axial force by 50%

* Reduction in radial force by 25%

* German technology at a fraction of the cost

COUNTER SINK: 31.0MM HSSCo 3 FLUTE 90° ANTI-CHATTER

SKU:

CTB300356

* These three flute countersink Bit are manufactured by Hartingen

* Special spiral flute 90 degree geometry with unequil helix angles

* High grade HSSCo substrates hold up well in high-tempreture applications

* Low vibration without chatter marks

* The tianin coating ensures higher wear resistance

* Reduction in axial force by 50%

* Reduction in radial force by 25%

* German technology at a fraction of the cost

CARBIDE THRU COOLANT FEED DRILL: 3D 3.0MM

SKU:

DBA210100

*These solid carbide drills are manufactured from quality Sub-Micron grade materials

* Through coolant drills offer several advantages, including: significantly improved chip evacuation, better heat control, extended tool life, increased cutting speeds and feeds, better surface finish, reduced cycle times, the ability to work with harder materials, and minimized risk of tool breakage due to effective cooling directly at the cutting edge, all leading to higher production efficiency and better overall hole quality.

CARBIDE THRU COOLANT FEED DRILL: 3D 3.2MM

SKU:

DBA210102

*These solid carbide drills are manufactured from quality Sub-Micron grade materials

* Through coolant drills offer several advantages, including: significantly improved chip evacuation, better heat control, extended tool life, increased cutting speeds and feeds, better surface finish, reduced cycle times, the ability to work with harder materials, and minimized risk of tool breakage due to effective cooling directly at the cutting edge, all leading to higher production efficiency and better overall hole quality.

CARBIDE THRU COOLANT FEED DRILL: 3D 3.5MM

SKU:

DBA210105

CARBIDE THRU COOLANT FEED DRILL: 3D 3.7MM

SKU:

DBA210107

*These solid carbide drills are manufactured from quality Sub-Micron grade materials

* Through coolant drills offer several advantages, including: significantly improved chip evacuation, better heat control, extended tool life, increased cutting speeds and feeds, better surface finish, reduced cycle times, the ability to work with harder materials, and minimized risk of tool breakage due to effective cooling directly at the cutting edge, all leading to higher production efficiency and better overall hole quality.

CARBIDE THRU COOLANT FEED DRILL: 3D 3.8MM

SKU:

DBA210108

*These solid carbide drills are manufactured from quality Sub-Micron grade materials

* Through coolant drills offer several advantages, including: significantly improved chip evacuation, better heat control, extended tool life, increased cutting speeds and feeds, better surface finish, reduced cycle times, the ability to work with harder materials, and minimized risk of tool breakage due to effective cooling directly at the cutting edge, all leading to higher production efficiency and better overall hole quality.

CARBIDE THRU COOLANT FEED DRILL: 3D 4.0MM

SKU:

DBA210120

*These solid carbide drills are manufactured from quality Sub-Micron grade materials

* Through coolant drills offer several advantages, including: significantly improved chip evacuation, better heat control, extended tool life, increased cutting speeds and feeds, better surface finish, reduced cycle times, the ability to work with harder materials, and minimized risk of tool breakage due to effective cooling directly at the cutting edge, all leading to higher production efficiency and better overall hole quality.

CARBIDE THRU COOLANT FEED DRILL: 3D 5.0MM

SKU:

DBA210130

*These solid carbide drills are manufactured from quality Sub-Micron grade materials

* Through coolant drills offer several advantages, including: significantly improved chip evacuation, better heat control, extended tool life, increased cutting speeds and feeds, better surface finish, reduced cycle times, the ability to work with harder materials, and minimized risk of tool breakage due to effective cooling directly at the cutting edge, all leading to higher production efficiency and better overall hole quality.

CARBIDE THRU COOLANT FEED DRILL: 3D 6.0MM

SKU:

DBA210140

*These solid carbide drills are manufactured from quality Sub-Micron grade materials

* Through coolant drills offer several advantages, including: significantly improved chip evacuation, better heat control, extended tool life, increased cutting speeds and feeds, better surface finish, reduced cycle times, the ability to work with harder materials, and minimized risk of tool breakage due to effective cooling directly at the cutting edge, all leading to higher production efficiency and better overall hole quality.

CARBIDE THRU COOLANT FEED DRILL: 3D 7.0MM

SKU:

DBA210150

*These solid carbide drills are manufactured from quality Sub-Micron grade materials

* Through coolant drills offer several advantages, including: significantly improved chip evacuation, better heat control, extended tool life, increased cutting speeds and feeds, better surface finish, reduced cycle times, the ability to work with harder materials, and minimized risk of tool breakage due to effective cooling directly at the cutting edge, all leading to higher production efficiency and better overall hole quality.

CARBIDE THRU COOLANT FEED DRILL: 3D 8.0MM

SKU:

DBA210160

*These solid carbide drills are manufactured from quality Sub-Micron grade materials

* Through coolant drills offer several advantages, including: significantly improved chip evacuation, better heat control, extended tool life, increased cutting speeds and feeds, better surface finish, reduced cycle times, the ability to work with harder materials, and minimized risk of tool breakage due to effective cooling directly at the cutting edge, all leading to higher production efficiency and better overall hole quality.

CARBIDE THRU COOLANT FEED DRILL: 3D 10.0MM

SKU:

DBA210170

*These solid carbide drills are manufactured from quality Sub-Micron grade materials

* Through coolant drills offer several advantages, including: significantly improved chip evacuation, better heat control, extended tool life, increased cutting speeds and feeds, better surface finish, reduced cycle times, the ability to work with harder materials, and minimized risk of tool breakage due to effective cooling directly at the cutting edge, all leading to higher production efficiency and better overall hole quality.

CARBIDE THRU COOLANT FEED DRILL: 3D 14.0MM

SKU:

DBA210190

*These solid carbide drills are manufactured from quality Sub-Micron grade materials

* Through coolant drills offer several advantages, including: significantly improved chip evacuation, better heat control, extended tool life, increased cutting speeds and feeds, better surface finish, reduced cycle times, the ability to work with harder materials, and minimized risk of tool breakage due to effective cooling directly at the cutting edge, all leading to higher production efficiency and better overall hole quality.

CARBIDE THRU COOLANT FEED DRILL: 3D 14.0MM

SKU:

DBA210190

*These solid carbide drills are manufactured from quality Sub-Micron grade materials

* Through coolant drills offer several advantages, including: significantly improved chip evacuation, better heat control, extended tool life, increased cutting speeds and feeds, better surface finish, reduced cycle times, the ability to work with harder materials, and minimized risk of tool breakage due to effective cooling directly at the cutting edge, all leading to higher production efficiency and better overall hole quality.

CARBIDE THRU COOLANT FEED DRILL: 3D 16.0MM

SKU:

DBA210200

*These solid carbide drills are manufactured from quality Sub-Micron grade materials

* Through coolant drills offer several advantages, including: significantly improved chip evacuation, better heat control, extended tool life, increased cutting speeds and feeds, better surface finish, reduced cycle times, the ability to work with harder materials, and minimized risk of tool breakage due to effective cooling directly at the cutting edge, all leading to higher production efficiency and better overall hole quality.

CARBIDE DRILL: 1.0MM HRC60 (SEA)

SKU:

DBA2106000