- Show All

- AUTO RECONDITIONING MACHINES

- AXLE STANDS

- BATTERY CHARGERS

- ENGINE STANDS

- GREASE & OILS

- HYDRAULIC BODY JACKS

- HYDRAULIC BOTTLE JACKS

- HYDRAULIC TOE JACKS

- HYDRAULIC TROLLEY JACKS

- HYD ENGINE CRANES

- HYD MOTORCYCLE LIFT

- HYD TRANSMISSION JACKS

- HYD SPRING COMPRESSOR

- HYD VEHICLE POSITIONING JACK

- GARAGE ESSENTIALS

- OIL DRAIN TANK

- PANEL BEATING EQUIPMENT

- WORKSHOP PRESSES

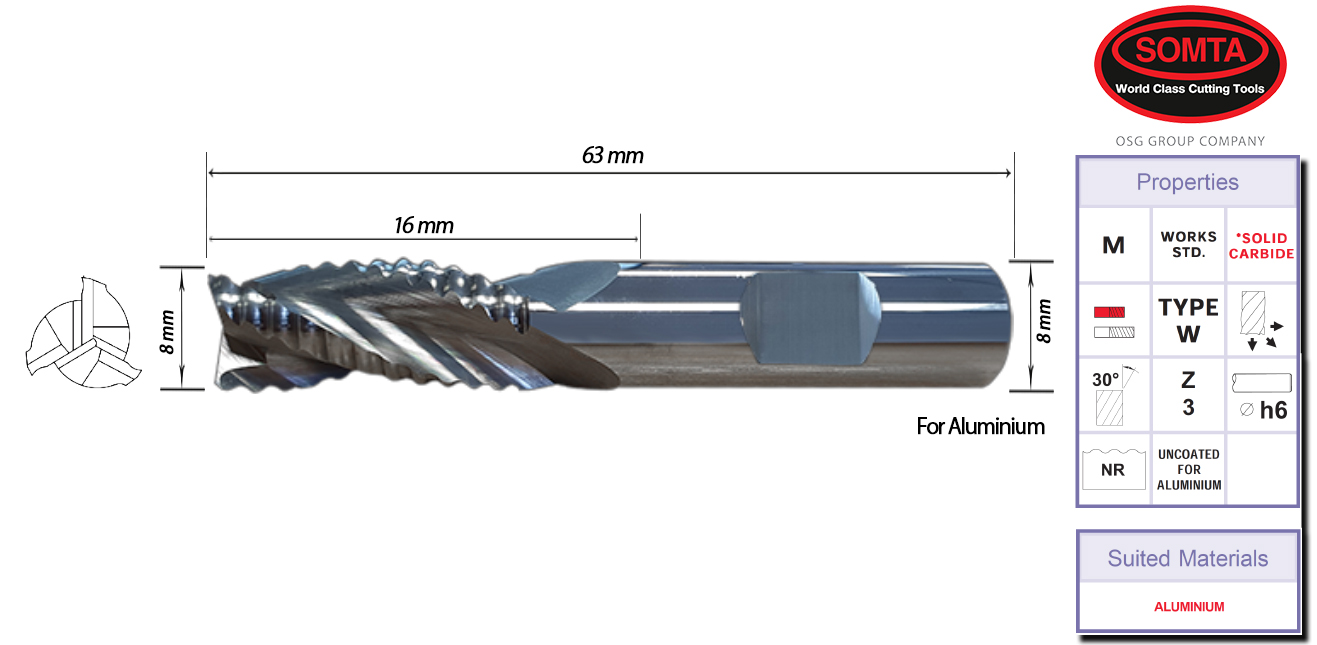

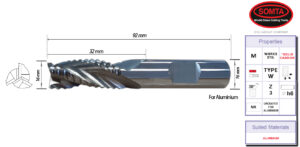

ROUGH E/MILL: FAST 8.0MM CARBIDE UNCOATED 3 FLUTE ALUMINUM (SOMTA)

$57.99

* Roughing Cutters in the round tool sector are better known as “RMR” cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability “To produce smaller chips per cm3/min (i3/min) of material machined”

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per * The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen

*The sacrfice is finish on these end mills is uncoated and are most suitable for aluminum *

| Weight | 0.055 kg |

|---|---|

| Dimensions | 0.1 × 0.03 × 0.03 cm |

In stock

SKU:

EM-7486080

Category: Roughing E/Mill

Description

| DESCRIPTION | Roughing End Mill |

|---|---|

| DIAMETER | 8.0MM |

| MATERIAL | Carbide |

| FLUTES | 3 Flute |

| LENGTH O/A | 63.0mm |

| FLUTE LENGTH | 16.0mm |

| SHANK DIAMETER | 8.0mm |

| SHANK TYPE | Flatted Shank |

| FINISH | Uncoated for Aluminum |

| SPEED AND FEED | Uncoated for Aluminum with High Speed and Feed. Speed 10,000 rpm Feed = 4,000 rpm. |

| DEPTH OF CUT | 5 – 10.0mm Depending on machine and grade of material |

| WEIGHT NETT/GROSS | 0.055kg |

| VOLUME | 0.0001cm |

Shipping & Delivery

Related products

ROUGH E/MILL: 6.0MM HSS STANDARD (SOMTA)

SKU:

EM-7485006

$39.00

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal). These tools are as per some of the other descriptions already posted on this thread. They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees. The cutting edge is broken into many segments that look like serations or multiple small radii * Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations * This is for obvious reasons that mainly lead to increased cutting edge strength * Having a broken edge has some benefts but also some draw backs * Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined" * By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per * The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut *

A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen *

The sacrfice is finish *

ROUGH E/MILL: 8.0MM HSS LONG-SERIES THREAD/SHANK(SOMTA)

SKU:

EM-7485208

$52.92

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal). These tools are as per some of the other descriptions already posted on this thread. They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees. The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per * The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

*A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen *

The sacrfice is finish *

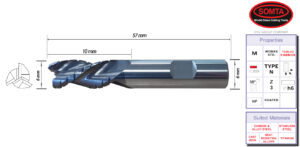

ROUGH E/MILL: FAST 6.0MM CARBIDE UNCOATED 3 FLUTE ALUMINUM

SKU:

EM-7486000

$37.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal) *They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees * The cutting edge is broken into many segments that look like serations or multiple small radii * Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations * This is for obvious reasons that mainly lead to increased cutting edge strength * Having a broken edge has some benefts but also some draw backs * Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined" * By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per * The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut * A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen *

The sacrfice is finish on these end mills is uncoated and are most suitable for aluminum *

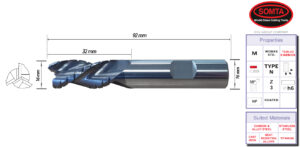

ROUGH E/MILL: FAST 12.0MM CARBIDE UNCOATED 3 FLUTE ALUMINUM (SOMTA)

SKU:

EM-7486120

$105.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen

*The sacrfice is finish on these end mills is uncoated and are most suitable for aluminum *

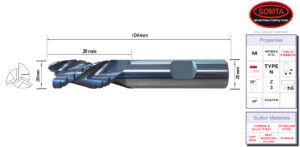

ROUGH E/MILL: FAST 16.0MM CARBIDE UNCOATED 3 FLUTE ALUMINUM

SKU:

EM-7486160

$182.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen

*The sacrfice is finish on these end mills is uncoated and are most suitable for aluminum *

ROUGH E/MILL: 6.0MM CARBIDE COATED STEEL 4 FLUTE (SEA)

SKU:

EM-7486206

$35.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen *

ROUGH E/MILL: 16.0MM CARBIDE COATED STEEL 4 FLUTE (SOMTA)

SKU:

EM-7486216

$174.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength * Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen *

ROUGH E/MILL: 25.0MM CARBIDE COATED STEEL 4 FLUTE (SEA)

SKU:

EM-7486225

$320.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen *