- Show All

- AUTO RECONDITIONING MACHINES

- AXLE STANDS

- BATTERY CHARGERS

- ENGINE STANDS

- GREASE & OILS

- HYDRAULIC BODY JACKS

- HYDRAULIC BOTTLE JACKS

- HYDRAULIC TOE JACKS

- HYDRAULIC TROLLEY JACKS

- HYD ENGINE CRANES

- HYD MOTORCYCLE LIFT

- HYD TRANSMISSION JACKS

- HYD SPRING COMPRESSOR

- HYD VEHICLE POSITIONING JACK

- GARAGE ESSENTIALS

- OIL DRAIN TANK

- PANEL BEATING EQUIPMENT

- WORKSHOP PRESSES

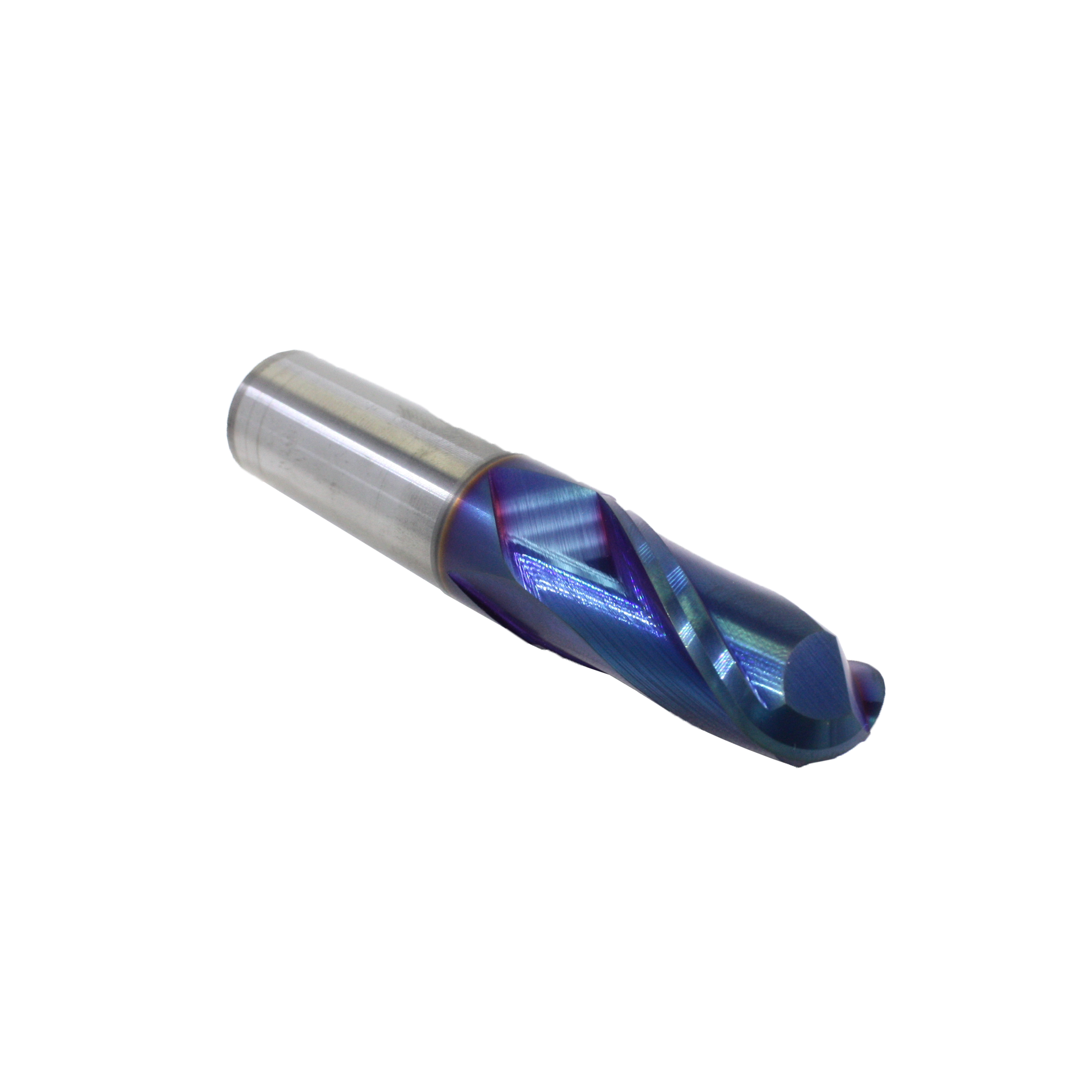

BALL NOSE: 18.0MM HRC65 CARBIDE COATED 2FL STD (SEA)

$0.00

* These ball nose 2 flute end mills are manufactured from quality verin carbide for durability and long service life

* Standard length General Purpose, 2 Flutes, Single End

* Ideal for radius Cutting, Right Hand Cut – Bright Finish

| Weight | 0.16 kg |

|---|---|

| Dimensions | 0.1 × 0.03 × 0.03 cm |

In stock

SKU:

EM-7302417

Category: Ball Nose Carbide

Description

| DESCRIPTION | Ball Nose End Mill |

|---|---|

| MATERIAL | Carbide HRC65 |

| DIAMETER | 18.0mm 2 Flute |

| LENGTH O/A | Standard |

| FLUTE LENGTH | 40.0mm |

| SHANK | 18.0mm |

| FINISH | AITiSiN Coated |

| WEIGHT NETT/GROSS | 0.160kg |

| VOLUME | 0.0001cm |

Shipping & Delivery

Related products

BALL NOSE: 6.0MM HRC65 CARBIDE COATED 2FL STD (SEA)

SKU:

EM-7302406

$44.00

* Quality milling machine cutting tool

* This is a 2 flute ball nose end mill which is manufactured from quality High Speed Steel for durability and long service life

* Extremely high performance. and Ideal for cutting a radius

* Ball nose end mill is a type of milling cutter used in machining operations to create contoured surfaces, curved profiles, and 3D shapes on a workpiece

* It gets its name from the spherical (ball-like) shape of the cutting end. Ball nose end mills are specifically designed for applications where intricate and curved features need to be milled.

* Ball nose end mill specifications include Ball Radius, Diameter, Shank Diameter, Overall Length, Flute Count, Helix Angle, Coating, and Material to define its form, size, features, and suitability for materials like steel, aluminum, or graphite

* These factors determine tool performance in 3D contouring, profiling, and finishing

BALL NOSE: 8.0MM HRC75 CARBIDE COATED 2FL STD (SEA)

SKU:

EM-7302408

$54.00

BALL NOSE: 12.0MM HRC65 CARBIDE COATED 2FL STD (SEA)

SKU:

EM-7302412

$68.00

BALL NOSE: CARBIDE COATED 4.0MM 2FL STD (SOMTA)

SKU:

EM-7340040A

$26.88

*These ball nose end mills are manufactured in USA from quality carbide for durability and long service life

* Solid carbide endmills for steel, cast, stainless steel, exotic materials, aluminum, non-ferrous materials and hardened steels

* These solid carbide endmills are made from ultra micrograin carbide.

* The grain size ranges from 0 - 0,5 micron and the coatings vary by application (TiAlN, TICN ).

* High performance, improved tool life, maximum cutting speed,

* Excellent wear resist and reliable quality, Cost effectiveness, Reduced wear ensures productivity, down time minimized, less tool changes *

BALL NOSE: CARBIDE 5.0MM 2FL STD (USA)

SKU:

EM-7340050

$34.94

*These ball nose end mills are manufactured in USA from quality carbide for durability and long service life

* Solid carbide endmills for steel, cast, stainless steel, exotic materials, aluminum, non-ferrous materials and hardened steels

* These solid carbide endmills are made from ultra micrograin carbide.

* The grain size ranges from 0 - 0,5 micron and the coatings vary by application (TiAlN, TICN ).

* High performance, improved tool life, maximum cutting speed,

* Excellent wear resist and reliable quality, Cost effectiveness, Reduced wear ensures productivity, down time minimized, less tool changes *

BALL NOSE: CARBIDE COATED 5.0MM 2FL STD (SOMTA)

SKU:

EM-7340050A

$34.94

*These ball nose end mills are manufactured in USA from quality carbide for durability and long service life

* Solid carbide endmills for steel, cast, stainless steel, exotic materials, aluminum, non-ferrous materials and hardened steels

* These solid carbide endmills are made from ultra micrograin carbide.

* The grain size ranges from 0 - 0,5 micron and the coatings vary by application (TiAlN, TICN ).

* High performance, improved tool life, maximum cutting speed,

* Excellent wear resist and reliable quality, Cost effectiveness, Reduced wear ensures productivity, down time minimized, less tool changes *

BALL NOSE: CARBIDE 1/8″ 2FL STD (INDEX)

SKU:

EM-7341250C

$19.00

* These ball nose end mills are manufactured ifrom quality carbide for durability and long service life

* Solid carbide endmills for steel, cast, stainless steel, exotic materials, aluminum, non-ferrous materials and hardened steels

* These solid carbide endmills are made from ultra micrograin carbide. The grain size ranges from 0 - 0,5 micron

* High performance, improved tool life, maximum cutting speed,

Excellent wear resist and reliable quality, Cost effectiveness, Reduced wear ensures productivity, down time minimized, less tool changes

BALL NOSE: CARBIDE 3/16″ 2FL STD (USA)

SKU:

EM-7341290

$41.66

* These ball nose end mills are manufactured in USA from quality carbide for durability and long service life

* Solid carbide endmills for steel, cast, stainless steel, exotic materials, aluminum, non-ferrous materials and hardened steels

* These solid carbide endmills are made from ultra micrograin carbide. The grain size ranges from 0 - 0,5 micron and the coatings vary by application (TiAlN, TICN ). High performance, improved tool life, maximum cutting speed,

Excellent wear resist and reliable quality, Cost effectiveness, Reduced wear ensures productivity, down time minimized, less tool changes