- Show All

- AUTO RECONDITIONING MACHINES

- AXLE STANDS

- BATTERY CHARGERS

- ENGINE STANDS

- GREASE & OILS

- HYDRAULIC BODY JACKS

- HYDRAULIC BOTTLE JACKS

- HYDRAULIC TOE JACKS

- HYDRAULIC TROLLEY JACKS

- HYD ENGINE CRANES

- HYD MOTORCYCLE LIFT

- HYD TRANSMISSION JACKS

- HYD SPRING COMPRESSOR

- HYD VEHICLE POSITIONING JACK

- GARAGE ESSENTIALS

- OIL DRAIN TANK

- PANEL BEATING EQUIPMENT

- WORKSHOP PRESSES

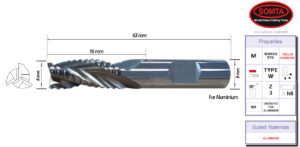

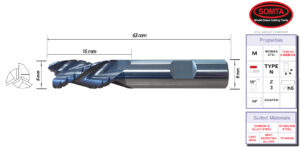

ROUGH E/MILL: FAST 10.0MM CARBIDE UNCOATED 3 FLUTE ALUMINUM

$77.99

* Roughing Cutters in the round tool sector are better known as “RMR” cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability “To produce smaller chips per cm3/min (i3/min) of material machined”

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen

*The sacrfice is finish on these end mills is uncoated and are most suitable for aluminum *

| Weight | 0.06 kg |

|---|---|

| Dimensions | 0.1 × 0.03 × 0.03 cm |

In stock

SKU:

EM-7486100

Category: Roughing E/Mill

Description

| DESCRIPTION | Roughing End Mill |

|---|---|

| DIAMETER | 10.0MM |

| MATERIAL | Carbide |

| FLUTES | 3 Flute |

| LENGTH O/A | 72.0mm |

| FLUTE LENGTH | 22.0mm |

| SHANK DIAMETER | 10.0mm |

| SHANK TYPE | Flatted Shank |

| FINISH | Uncoated for Aluminum |

| SPEED AND FEED | Speed 10,000 rpm Feed = 4,000 rpm. |

| DEPTH OF CUT | 5 – 10.0mm Depending on machine and grade of material |

| WEIGHT NETT/GROSS | 0.060kg |

| VOLUME | 0.0001cm |

Shipping & Delivery

Related products

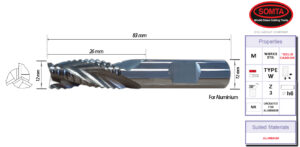

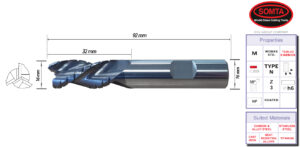

ROUGH E/MILL: FAST 12.0MM CARBIDE UNCOATED 3 FLUTE ALUMINUM (SOMTA)

SKU:

EM-7486120

$105.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen

*The sacrfice is finish on these end mills is uncoated and are most suitable for aluminum *

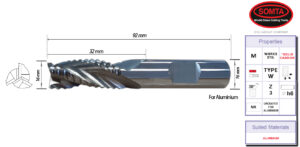

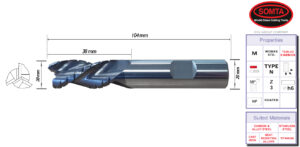

ROUGH E/MILL: FAST 16.0MM CARBIDE UNCOATED 3 FLUTE ALUMINUM

SKU:

EM-7486160

$182.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen

*The sacrfice is finish on these end mills is uncoated and are most suitable for aluminum *

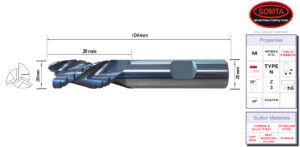

ROUGH E/MILL: FAST 20.0MM CARBIDE UNCOATED 3 FLUTE ALUMINUM

SKU:

EM-7486200

$221.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen

*The sacrfice is finish on these end mills is uncoated and are most suitable for aluminum *

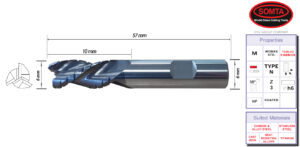

ROUGH E/MILL: 6.0MM CARBIDE COATED STEEL 4 FLUTE (SEA)

SKU:

EM-7486206

$35.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen *

ROUGH E/MILL: 8.0MM CARBIDE COATED STEEL 4 FLUTE (SOMTA)

SKU:

EM-7486208

$43.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen *

ROUGH E/MILL: 16.0MM CARBIDE COATED STEEL 4 FLUTE (SOMTA)

SKU:

EM-7486216

$174.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength * Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen *

ROUGH E/MILL: 20.0MM CARBIDE COATED STEEL 4 FLUTE (SEA)

SKU:

EM-7486220

$278.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen *

ROUGH E/MILL: 25.0MM CARBIDE COATED STEEL 4 FLUTE (SEA)

SKU:

EM-7486225

$320.99

* Roughing Cutters in the round tool sector are better known as "RMR" cutters (Rapid Metal Removal)

*They (more commonly) will incoporate a typical spiral helix shape of multiple flutes which is a helix of between 20 and 40degrees

* The cutting edge is broken into many segments that look like serations or multiple small radii

* Tradesmen are of the opnion that the best RMR designs are ones that incorporate rounder profile serations

* This is for obvious reasons that mainly lead to increased cutting edge strength

* Having a broken edge has some benefts but also some draw backs

* Ultimately, all you really get is the ability "To produce smaller chips per cm3/min (i3/min) of material machined"

* By getting lots of smaller chips, you are able to get much better smarf removal/control and therefore, in some cases, are able to run a higher D.O.C (depth of cut) and/or f/z (feed per

* The main reasons for RMR cutters being in existence is lower cutting forces, higher tool life and less bending when milling a shoulder at a high depth of cut

* A broken edge greatly lowers the forces generated on the cutting edge. This can be a reduction of as much as 50% and an increase in tool life of as much as 50% can also be seen *